Plastic Powder Coating Services

Ask Us A QuestionPowder coating plastics (ClassicKote) is a proprietary pvc powder coating technique developed by Wright to successfully coat “non-conductive” nylon reinforced plastic with decorative and protective color and clear powder coatings. Our ClassicKote process provides all the benefits of traditional Powder Coating plus additional advantages unique to plastic applications for numerous industries: Office Furniture, Appliance, Automotive, Seating, Electronics, Consumer Goods, and custom applications.

Our specialty industrial & commercial plastic coatings application expertise has enabled us to efficiently and successfully coat high-temperature plastic parts with decorative and protective color and clear powder coatings, take a look at our case study. We are an ISO 9001:2015 registered powder coatings applicator.

Powder-coated plastic substrates allow for easy transition from metal to plastic parts and are available in a variety of colors.

Plastic Powder Coating Advantages

There are several advantages to powder coating over conventional liquid coatings:

- Powder coatings emit zero or near zero volatile organic compounds (VOC)

- Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging

- Powder coating overspray can be recycled making it possible to achieve nearly 100% use

- Powder coating production lines produce less hazardous waste than conventional liquid coatings

- Powder-coated items generally have fewer appearance differences between horizontally and vertically coated surfaces than liquid coated items

- A wide range of specialty effects are easily accomplished which would be impossible with other coating processes

- Able to handle small parts up to 30” x 60” x 40”

Technical Information

Performance Properties

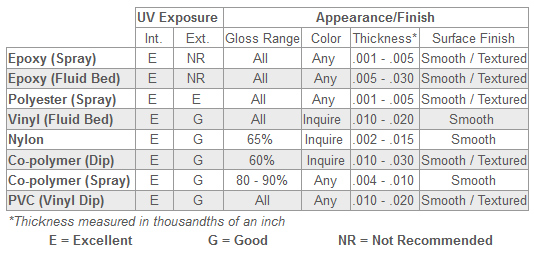

The industrial & commercial plastic coatings we apply can be used to meet a variety of performance requirements based on your particular needs. You may wish to refer to this table to identify the most appropriate coating for your application:

For more information on our plastic powder coating services and how we can tailor to your specific needs, contact the team at Wright Coating Technologies.

What Plastics can be coated?

Wright Coating Can powder coat many plastics, but some are not durable enough to withstand the heat necessary for most coating or dipping methods. Below is a list of plastics we are able to coat. If you do not see your material here, reach out for more information!

- 35% LGF nylon 6 GE PDX-P-00700

- 43% SGF nylon 6 Omni PA6 GR43 EF NA

- 33% glass-filled nylon 66, BH polymers

- 14% glass-filled nylon 66, DuPont Zytel 8018HSBK085

- Ultramid® 8233G HS nylon 6 glass filled

- 33% GF nylon 6 DSM Akulon J-3/30

- OmniPA6 GR30NA

- Omni PA6 GR33 NA

- Omni PA6 GR33 BK2000

- Omni PA6 33% glass-filled nylon (DSM Akulon K224-G6U)

- 30% Natural GF nylon

- 30% GF PA6 DSM K224G6U

- TP composites

- Elastoblend® nylon PA6/6, 6 IML

- Elastoblend® nylon PA6/6 HI BK Nylon 66

- Maxamid™ EPDM 206-BK10

- Nylon 6 Omni PA6 GR30 NA

Application Methods

Epoxy (Electrostatic Spray) – Epoxy-based Electrostatic Spray powder coating is used to protect metal substrates such as steel and aluminum from corrosion in a variety of applications.

Epoxy coatings are Thermoset Polymer coatings that come under the category of 'protective coatings' in paints and coating nomenclature. Epoxy-based Electrostatic Spray powder coating is applied through a spray process where the part is electrostatically sprayed with a dry powder that is fluidized with air and then post cured. Electrostatic Sprayed Epoxy is generally applied at a thickness of 1.5 – 4.5 mils (thousandths of an inch). The name “Epoxy” is due to resin cross-linking and the application method, which is different from conventional paint. The resin and hardener components in the dry powder form do not react in normal storage conditions. Typical coating application temperatures range from 180°C to 250 °C (360°F to 480 °F). Epoxy-based powders are not recommended for exterior applications.

Epoxy (Fluid Bed) – Epoxy-based Fluid Bed powder coating is often used to protect metal substrates like steel and aluminum, in a wide variety of applications, from corrosion.

Epoxy fluid bed coatings are thermoset Polymer coatings. They fall under the category of 'protective coatings' in paints and coating nomenclature. The Fluid Bed process is most often used when a part requires a thicker coating compared to electrostatic spray powder. The Fluid Bed Epoxy coating is applied through a dip process where the part is preheated and dipped into a dry powder that is fluidized with air then post cured. Fluid Bed Epoxy is generally applied at a thickness of 5 – 30 mils (thousandths of an inch). The resin and hardener components in the dry powder form do not react in normal storage conditions. Typical coating application temperatures range from 180°C to 250 °C (360°F to 480 °F). Epoxy-based powders are not recommended for exterior applications.

Polyester (Electrostatic Spray) – Polyester-based Electrostatic Spray powder coating is used to protect a variety of metal substrates, including steel and aluminum, for a variety of applications from corrosion.

Polyester coatings are thermoset Polymer coatings. They are in the category of 'protective coatings' in paints and coating nomenclature. Polyester electrostatic spray powder coating is applied through a spray process where the part is electrostatically sprayed with a dry powder, fluidized with air and then post cured. Electrostatic Sprayed Polyester is usually applied at a thickness of 1.5 – 4.5 mils (thousandths of an inch). The name Polyester is due to resin cross-linking and the application method, which is different from conventional paint. The resin and hardener components in the dry powder form do not react in normal storage conditions. Coating application temperatures range from usually between 180°C to 250 °C (360°F to 480 °F). Polyester-based powders are recommended for interior and exterior applications.

Wright Coating Technologies is proud to announce that we have expanded our current offerings to provide Soft Touch Powder Coating. This unique coating provides parts with durable protection and is soft to the touch. Our environmentally safe Soft Touch Coating is available in many colors, and can be applied to even the most complex parts.