Custom Commercial & Industrial Powder Coating Services

Ask Us A QuestionWright Coating Technologies offers four (4) unique Powder Coating lines to match your job requirements for your industrial or commercial application. All four lines incorporate automated and manual processing. There is a wide array of colors available for both functional and aesthetic applications.

Our commercial and industrial powder coating services are extensive, impressive, and one of our most requested specialty coating applications. We are an ISO 9001:2015 registered coatings applicator that places a strong emphasis on meeting and exceeding expectations to ensure quality powder coatings.

Applications are also available for applying Epoxies, Polyesters, Urethanes, Vinyl, and Nylons.

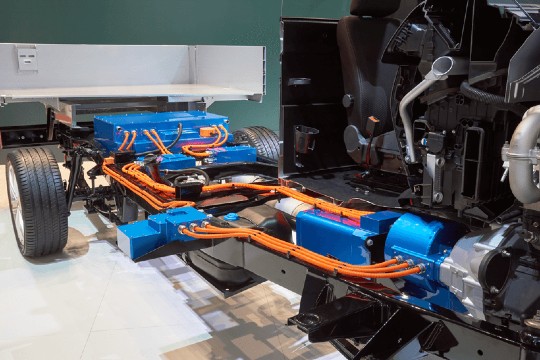

Wright has developed expertise in a wide range of industries, including applying powder coatings for the electric vehicles, alternative energy, appliance, automotive, consumer goods, metal fabricator, fitness equipment, outdoor grills, and office furniture industries. We also provide very cost-effective coating solutions to resolve BSR and NVH issues in the automotive industry. We provide these and many more custom powder coating services as needed.

Powder Coating Versus Painting

Powder coatings provide better performance than traditional wet painting as it is more rugged and resistant to corrosion, chemicals, and weathering. Powder-coated surfaces also resist chipping, scratching, and other wear much more effectively than wet paint. Typically wet paint should be used in applications where the material being finished cannot withstand the heat necessary for powder coating. In nearly every other scenario, powder coating is more superior. Powder coatings are less expensive in comparison to paint and can cover more area than most finishers, which means lower material costs than wet painting processes.

Traditional wet paint is also extremely flammable and contains carcinogens and volatile organic compounds (VOCs). Not surprisingly, these chemicals are hazardous to plant employees if proper precautions are not met. Powder coatings do not contain VOCs and are without solvents, meaning they pose much less of a chemical risk to workers. Beyond being a risk to workers, VOCs and solvents also create a pollution concern. Powder coating is a much cleaner process, as well. Overspray can be gathered and reused, and unused powder can be retrieved and put back in a hopper for recirculation, eliminating a lot of waste.

What Are The Advantages of Powder Coating?

There are several advantages to powder coating over conventional liquid coatings:

- Powder coatings emit zero or near zero volatile organic compounds (VOC)

- Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging

- Powder coating overspray can be recycled making it possible to achieve nearly 100% use

- Powder coating production lines produce less hazardous waste than conventional liquid coatings

- Powder-coated items generally have fewer appearance differences between horizontally and vertically coated surfaces than liquid coated items

- A wide range of specialty effects are easily accomplished which would be impossible with other coating processes

- Able to handle small parts up to 26” x 12” x 52”

Technical Information

Performance Properties

As custom powder coating applicators, the coatings we apply can be used to meet a variety of performance requirements based on your particular needs. You may wish to refer to this table to identify the most appropriate coating for your application:

| UV Exposure | Appearance/Finish | |||||

|---|---|---|---|---|---|---|

| Int. | Ext. | Gloss Range | Color | Thickness | Surface Finish | |

| Epoxy (Spray) | E | NR | All | Any | 0.001-0.005 | Smooth/ Textured |

| Epoxy (Fluid Bed) | E | NR | All | Any | 0.005-0.030 | Smooth/ Textured |

| Polyester (Spray) | E | E | All | Any | 0.001-0.005 | Smooth/ Textured |

| Vinyl (Fluid Bed) | E | G | All | Inquire | 0.010-0.020 | Smooth |

| Nylon | E | G | 65% | Inquire | 0.002-0.015 | Smooth |

| Co-polymer (Dip) | E | G | 60% | Inquire | 0.010-0.030 | Smooth/ Textured |

| Co-polymer (Spray) | E | G | 80-90% | Any | 0.004-0.010 | Smooth |

| PVC (Vinyl Dip) | E | G | All | Any | 0.010-0.020 | Smooth/ Textured |

*Thickness measured in thousandths of an inch

E=Excellent G=Good NR=Not Recommended

Application Methods

Commercial & Industrial Powder Coating Methods

Epoxy (Electrostatic Spray) – Epoxy-based Electrostatic Spray powder coating is widely used to protect a variety of metal substrates, i.e. steel & aluminum, for a wide variety of applications from corrosion. Epoxy coatings are Thermoset Polymer coatings. They come under the category of 'protective coatings' in paints and coating nomenclature. Epoxy-based Electrostatic Spray powder coating is applied through a spray process where the part is electrostatically sprayed with a dry powder that is fluidized with air and then is post cured. Electrostatic Sprayed Epoxy is generally applied at a thickness ranging from 1.5 – 4.5 mils (thousandths of an inch). The name “Epoxy” is due to resin cross-linking and the application method, which is different from conventional paint. The resin and hardener components in the dry powder form do not react in normal storage conditions. Typical coating application temperatures are usually in the range of 180°C to 250 °C (360°F to 480 °F). Epoxy-based powders are not recommended for exterior-type applications.

Epoxy (Electrostatic Spray) – Epoxy-based Electrostatic Spray powder coating is widely used to protect a variety of metal substrates, i.e. steel & aluminum, for a wide variety of applications from corrosion. Epoxy coatings are Thermoset Polymer coatings. They come under the category of 'protective coatings' in paints and coating nomenclature. Epoxy-based Electrostatic Spray powder coating is applied through a spray process where the part is electrostatically sprayed with a dry powder that is fluidized with air and then is post cured. Electrostatic Sprayed Epoxy is generally applied at a thickness ranging from 1.5 – 4.5 mils (thousandths of an inch). The name “Epoxy” is due to resin cross-linking and the application method, which is different from conventional paint. The resin and hardener components in the dry powder form do not react in normal storage conditions. Typical coating application temperatures are usually in the range of 180°C to 250 °C (360°F to 480 °F). Epoxy-based powders are not recommended for exterior-type applications.

Epoxy (Fluid Bed) – Epoxy-based Fluid Bed powder coating is widely used to protect a variety of metal substrates, i.e. steel & aluminum, for a wide variety of applications from corrosion. Epoxy Fluid Bed coatings are Thermoset Polymer coatings. They come under the category of 'protective coatings' in paints and coating nomenclature. The Fluid Bed process is generally used when a part requires a thicker coating as compared to electrostatic spray powder coating. The Fluid Bed Epoxy coating is applied through a dip process where the part is preheated and dipped into a dry powder that is fluidized with air and then posts cured. Fluid Bed Epoxy is generally applied at a thickness ranging from 5 – 30 mils (thousandths of an inch). The name “Epoxy” is due to resin cross-linking and the application method, which is different from conventional paint. The resin and hardener components in the dry powder form do not react in normal storage conditions. Typical Epoxy coating application temperatures are usually in the range of 180°C to 250 °C (360°F to 480 °F). Epoxy-based powders are not recommended for exterior-type applications.

Polyester (Electrostatic Spray) – Polyester-based Electrostatic Spray powder coating is widely used to protect a variety of metal substrates, i.e. steel & aluminum, for a wide variety of applications from corrosion. Polyester coatings are Thermoset Polymer coatings. They come under the category of 'protective coatings' in paints and coating nomenclature. Polyester Electrostatic spray powder coating is applied through a spray process where the part is electrostatically sprayed with a dry powder that is fluidized with air and then is post cured. Electrostatic Sprayed Polyester is generally applied at a thickness ranging from 1.5 – 4.5 mils (thousandths of an inch). The name Polyester is due to resin cross-linking and the application method, which is different from conventional paint. The resin and hardener components in the dry powder form do not react in normal storage conditions. Typical coating application temperatures are usually in the range of 180°C to 250 °C (360°F to 480 °F). Polyester-based powders are recommended for both interior and exterior type applications.

For more information on our commercial & industrial powder coating services, contact the team at Wright Coating Technologies today! Learn more about our powder coating services IN (Indiana).